SkateboardingUniversity.com Presents

The Online Skateboarding School

The Online Skateboarding School

"No Skateboarder Left Behind"

The Skateboard Equipment Class 101

CHAPTER 3

The Skateboard Trucks

Chapter 3 Objectives

Skateboard Trucks Parts

Work On the Trucks

Assemble Skateboard Trucks

Best Trucks for You

To Explore and Understand:

Section One

The Skateboard Trucks

The Skateboard Trucks

REMEMBER

The person with the highest test grade out of every class will get a free skateboard deck as a prize!

The person with the highest test grade out of every class will get a free skateboard deck as a prize!

At the bottom of each chapter is a 10 question quiz. So read all of the material, do your homework, and watch the videos!

Today's Homework: Take your truck's completely apart and put them back together.

The Skateboard trucks are critical to how a skateboard rides. Each skateboard has two trucks that function very similar to a car's axle. They give the ability of the skateboarder to control the skateboards direction by leaning his body weight to the right or left. Another function is to connect the wheels to the skateboard deck by the base plate. Most trucks are made out of aluminum alloy metal and are gray in color. It's getting more and more common to find them in a variety of colors like the picture on the left. Unsafe and very cheap trucks are made from plastic and some are made of plastic and metal combined. Do not use plastic trucks.

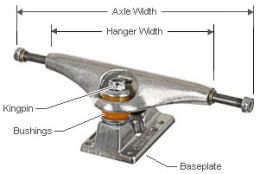

The Axle is a metal round rod that is positioned inside the hanger and extends on both sides. The bearings of the skateboard spin around it. Each end of the axle has threads that you can attach a nut and washer. The length of the axle is the width of the truck and should be the exact size of your skateboard or at least within 1/4 inch of it. The length of it determines the size of the truck. A common problem with axles are that they have a tendency to slip after much use, causing the wheels to stick. This makes the truck unusable. When this happens you can bang the axle on

The base plate is the base of the skateboard truck. It is a flat metal piece with four holes in it. The holes are for the hardware. The base plate lies flat on the bottom of the deck's surface. The side of the base plate that has the kingpin sticking out of it will always be facing the inside of the deck. In some cases people use riser pads that go in between the base plate and the skateboard deck to give more room for the wheels.

Section Two

Assembling A Skateboard Truck

Copy Right (c) 2010 All Rights Preserved www.skateboardinguniversity.com

the side to slide it back into place. This is only a temporary fix, because the problem will continue to get worst meaning it's the end of the life of your trucks. Because of technology and how it has changed the way skate trucks are designed you can now buy some that have a slip free axle. So the solution is simple, only buy trucks that have a non slip axle, because they have a money back guarantee if it slips.

Another problem that happens with the axles is that the threads sometimes get damaged or stripped causing the bolt to fall off. This can be extremely dangerous because your wheel can come off at any moment causing you to crash unexpectedly. There are only two ways that could possibly work in this situation. The first one calls for a electric grinder to make the job a piece of cake or if you do not have one of those around get a metal filer. Then you just grind down the tip of the axle until it looks new. Another very effective way is to buy a 5/16" re-threader. You twist it onto the axle and it will re-thread itself. To prevent this from happening in the first place be very careful whenever you are screwing the nuts onto your axle.

Learning The Parts Of A Skateboard Truck

The Kingpin

The Kingpin gets its name because it is the biggest bolt on a complete skateboard as well as it has the biggest responsibly for the skate truck. It holds together the entire truck by mounting the hanger onto the base plate. The bushings also are placed onto the kingpin. It is held together by one nut. The tightness of this nut has a direct effect on how loose or tight your skateboard is when it turns. The looser the nut is on the kingpin the quicker that skateboard turns. If it is tight the skateboard will be harder to turn. These bolts take a lot of beating and bear a lot of pressure. Sometimes the pressure is more than they can handle and

The Bushings

In the beginning a lot of skateboarders depend on the workers of skateboard shops to fix and work on their skateboards. It's a great convenience, but it pays to learn how to do it yourself right from the start. If you can figure out how to take a truck completely apart and put it back together, you have learned 90% of everything you have to know when it comes to working on skateboard trucks.

Watch Video Of Nick Explaining The Parts Of A Skateboard Truck

Before I explain this, the most important thing to ask yourself is how tight should you skate your trucks? It all depends on what kind of skateboarding you are going to do and how long you have been skateboarding.

Loose Trucks: They make it super easy to turn, so they are good in small bowls and in a tight skate park setting. Usually the more advanced skater skates with loose trucks. The benefit is you can turn super easy. If you are a beginner trying to learn some new tricks like an Ollie or a Kickflip then loose trucks will make it harder to learn. You would have to focus on balancing as well as doing the trick.

Medium Trucks: A recent skate pole showed that most skateboarders skate medium trucks. They are good if you skate a little bit of everything. It makes it so that you can still turn the board while moving fairly easy as well as having good balance to pull off tricks. Medium skateboard trucks are what I recommend to all beginners. They are right in the middle making it easier for new skateboarders to figure out how they like their trucks. Then they decide whether to tighten or loosen them.

Tight Trucks: Tight trucks are sometimes hard to turn. They are good for a few reasons. The first is if you are skating a vert ramp or places that you are really hauling. They will stop you from getting speed wobble as easily. Speed wobble is when your going down a hill and the trucks start to wobble back and forth out of control. The second reason is for skateboarders who are attempting to learn how to skate down stairs, ledges, and gaps. It stops you from getting wheel bite and sticking. Wheel bite is when the truck bends so much from impact that the wheel touches the deck, causing the board to stop rolling.

So now, how do you adjust your skateboard trucks? It's easy, it just requires turning the bolt on your kingpin to the right to tighten or to the left to loosen. Unless you have done it for a while its very hard to tell how loose or tight the trucks are by your hands. So after every half spin on each truck you should stand on the board to feel the difference.

If after all of your loosening and tightening of the trucks and they still won't skate the way you want them to, maybe you should look into getting a different firmness of bushings. If you are skating new trucks, they need some time to be broken in. So the more you skate everyday, the better they will feel!

The skater uses the trucks also to grind objects such as metal poles or waxed cement ledges. You can purchase one pair of trucks for anywhere between $25-$55. In the early days of skateboarding people would take a pair of roller skates and cut the trucks and wheels off and screw them into a sheet of wood. The first official skateboard truck companies started to pop up on the scene around the early 1980's. The Independent Truck Company was one of he first and had an important part in the designing of skateboard trucks. The other two big players were Bennett Trucks and Tracker Trucks. As skateboarding got more popular the demand for good quality trucks grew. This is when they started using the latest technology to design top of the line skateboarding trucks. There are currently over a dozen well known skateboard truck companies.

The Axle

The other thing that can really mess the axle up is if you break a bearing while skateboarding and neglect to take it out and put in a new one. The broken bearing will grind down the axle and sometimes make it unfixable. Just remember if your skateboard is ever riding funny, get off it immediately and find out what is causing it to act up. Fix it right away!

A Rethreader

The Hanger

The hanger is the piece of metal that the axle goes through. The back of it has a triangle shape. The kingpin is placed through the round hole in the hanger and holds it into the base plate. This is the part of the truck that all of your skateboard grinds are done on. There are different color hangers that you can buy. Its the main part of the truck that you can see with your eyes so I have known people to take their trucks apart and spray paint just the hanger of the truck and put it back together. If you spray paint the whole truck it will stick and not work properly, but if you spray paint just the hanger, it will still work perfect. If you do this, make sure that you cover the axle up with duck tape first so that it doesn't get any paint on it!

These are the rubbery round parts with a hole in the middle. They are on the kingpin separated by the hanger. There are 2 different size bushings per truck. The bigger bushing of the two goes onto the bottom of the truck closest to the base plate. This bushing effects the overall flex of the skateboard truck. The smaller top bushing helps to make a more accurate adjustment for how tight or loose the trucks are. Bushings wear out based on how much you skate and also the weather, because they shrink and enlarge by the cold and heat. You should replace your bushings about every 3 months to keep them feeling fresh. You can tell they are getting old because your board will

they snap into two pieces. If his happens do not worry because you can cheaply replace just the kingpin. To do this you take the truck off of the skateboard, take the nut off the kingpin, remove the hanger and bushing, and either screw it out of the base plate or bang it out with a hammer.

not turn as good and little pieces will start to flake off. They come in three different textures; soft, medium, and hard. The softer ones turn very easy, while the hard ones make the skateboard turn harder.

The Base Plate

Watch This Quick Video On Assembling A Skateboard Truck

Steps To Putting A Skateboard Truck Together

1) Slide the kingpin into the inside of the base plate.

2) Put the first washer which is the bigger one onto the kingpin right side up.

3) Find the bigger bushing out of the two and put it next onto the kingpin.

4) Next goes the hanger. Place it where the pointed part goes into the hole of the baseplate. Then spin it until the hole in the hanger goes on the kingpin.

4) Next goes the hanger. Place it where the pointed part goes into the hole of the baseplate. Then spin it until the hole in the hanger goes on the kingpin.

5) Find the smaller bushing and slide it onto the kingpin.

6) Set the smaller washer on top of the bushing.

7) Then your last step is to just tighten the nut onto the kingpin. Use a skate tool or a wrench to tighten it up. Stand on the board and lean to the right or left to see if the trucks are the way that you like them. Then tighten it more if you want them tighter.

A Fun Fast Video Showing How To Put trucks Onto A Skateboard

How To Tighten And Loosen Skateboard Trucks

Buy Yourself A Skateboard Tool

You can always use regular screw drivers and wrenches to work on your skateboard, but nothing beats having a skateboard tool. They are so cheap and can save you tons of stress and time. It is a pain trying to find the right size wrenches. A skate tool is small and has everything in one place that you will ever need to work on your skateboard. It has a screw driver that comes out of it, and three different size wrenches.

A Skateboard Tool